Industrial Hydraulic Cylinders

(Total 13 Products)

-

Customizable metallurgical hydraulic cylinder

Contact Now

-

petroleum two stage double acting lifting hydraulic cylinder

Contact Now

-

Hydraulic cylinder for heavy metallurgical industry

Contact Now

-

-

Integrated electric magnetic induction cylinder

Contact Now

-

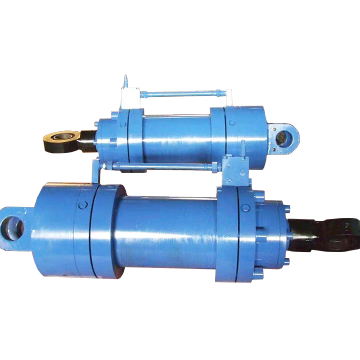

Petroleum machinery locking hydraulic cylinder

Contact Now

-

Hydraulic cylinder with balance valve for oilfield equipment

Contact Now

-

-

-

Customized hydraulic cylinders for hydraulic engineering

Contact Now

-

Customized hydraulic cylinder for wind power engineering

Contact Now

-

-

-

# **Product Overview**

This product is a high-performance hydraulic actuator specially designed for extreme working conditions in the metallurgical industry. It is suitable for key production processes such as continuous casting machines, steel...

-

**Product Introduction of Double-End Double-Action Lifting Cylinder**

# Product Overview

The double-ended double-acting lifting cylinder is a high-performance hydraulic actuator with **bidirectional synchronous drive**, featuring a **symmetrical...

-

Heavy chemical industry hydraulic cylinders are specialized products designed to meet the unique demands of the heavy chemical sector.

# **1. Product Overview**

Heavy-duty chemical industry hydraulic cylinders are specially designed for extreme...

-

The fast forging hydraulic cylinder is a high-performance hydraulic actuator specifically designed for fast forging equipment (fast forging machines, forging presses), featuring high-frequency response, shock resistance, and long service life. It is...

-

Magnetic induction cylinder is a hydraulic cylinder integrated with magnetostrictive displacement sensor, which can detect piston position in real-time and with high precision. It is widely used in hydraulic systems that require closed-loop...

-

**Product Introduction of Special Locking Hydraulic Cylinder for Oilfield Equipment**

# **Product Overview**

This locking hydraulic cylinder is specifically designed for oilfield equipment (such as production trees, blowout preventers, well...

-

Product Introduction of Hydraulic Cylinder with Balance Valve # Product Overview

The hydraulic cylinder with a balance valve is a safety-type hydraulic actuating component that integrates a balance valve. It is specifically designed for heavy-duty...

-

**Heavy-duty Pull Rod Hydraulic Cylinder Product Introduction**

# **Product Overview**

The heavy-duty lever hydraulic cylinder is designed with a high-strength lever structure, specifically developed for high-load and high-impact working...

-

**Introduction to Light-duty Pull Rod Oil Cylinders**

**Product Overview**

The lightweight telescopic cylinder adopts a **compact lever structure**, featuring light weight, flexible installation, and strong resistance to uneven loads. It is...

-

**Product Introduction of Hydraulic Cylinders for Hydraulic Engineering** The hydraulic oil cylinder for water conservancy is specially designed for tasks such as gate opening and closing, dam control, and dredging equipment. It features...

-

Our hydraulic cylinders for wind power engineering are designed to meet the specific requirements of the wind.Wind power hydraulic cylinders are key actuating components in wind power generation equipment, mainly used in critical parts such as pitch...

-

Valve in Cylinder is a hydraulic actuator that integrates hydraulic valve groups (such as directional valves, throttle valves, balance valves, etc.) directly inside or near the cylinder.

1. Main types

**(1) Classified by valve group position**

|* *...

-

1、 Main types and characteristics

|* * Classification criteria * * | * * Type * * | * * Characteristics and application scenarios *...

1. Industrial cylinders are the core actuating components of hydraulic systems, driving the piston to perform linear or oscillating movements through hydraulic oil, and outputting powerful thrust or pull.

2. They are widely used in fields such as construction machinery, metallurgy, and injection molding machines, and are suitable for scenarios with heavy loads, high precision, or long strokes.

3. The structure is simple but requires strict sealing and pressure-resistant design. Maintenance focuses on preventing leakage and wear to ensure long-term stable operation.