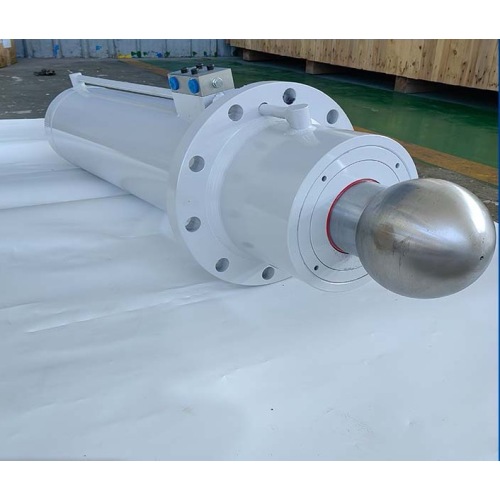

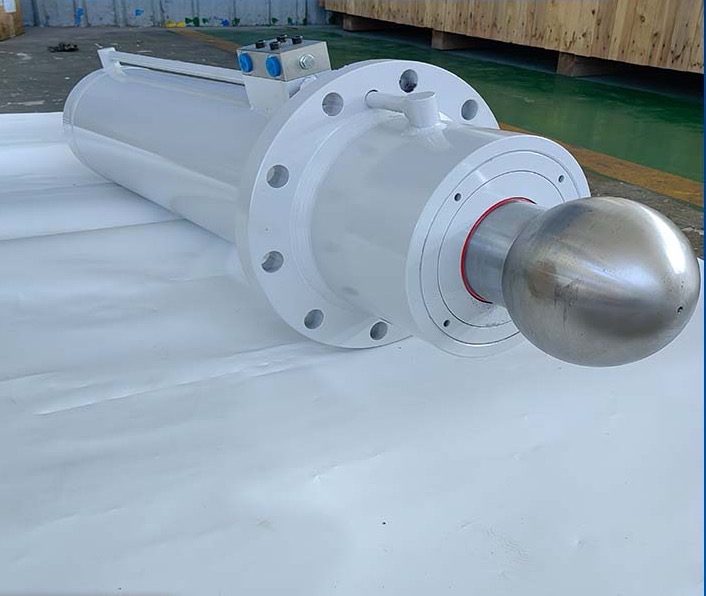

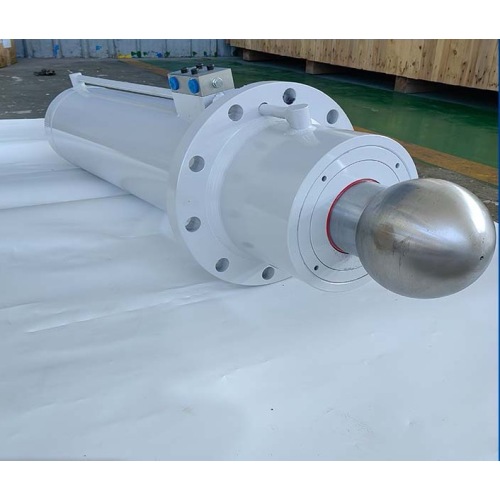

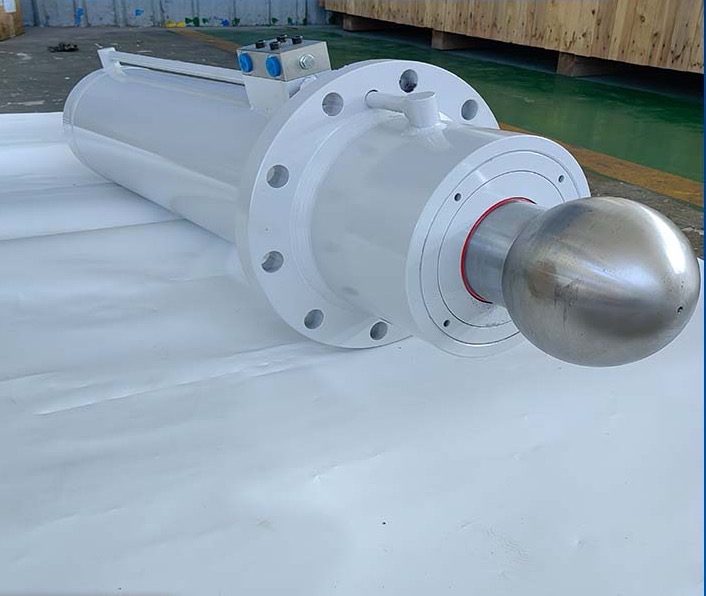

# **Product Overview**

This product is a high-precision Hydraulic Actuator specifically designed for log cutting equipment, used to drive key actions such as saw blade feed, log clamping, and transportation positioning. It features a heavy-duty precision design, with powerful output and millimeter-level motion control capabilities, and is the core power component of an automated wood processing production line.

---

**Core Technological Innovation**

# **1. Precise Motion Control**

- Displacement accuracy ±0.1mm (equipped with magnetostrictive sensors)

- Low-speed stability ≤ 5mm/s (no crawling phenomenon)

- Multi-stage electronic travel control (supports PLC programming)

# 2. Anti-pollution Reinforced Design

- Ceramic coating on the piston rod (friction coefficient < 0.05)

- Three-level filtration protection system (includes a 10μm filter)

- Self-cleaning dust shield (patent number ZL2023XXXXXX)

# 3. Intelligent Safety System

- Automatic overload relief protection (35MPa safety valve)

- Real-time temperature monitoring (PT100 sensor integrated)

- Abnormal vibration warning (IoT remote monitoring option available)

---

**Technical Specifications**

| **Project** | Standard Type | Overloaded Type | |-------------------|------------------|------------------|

| Work Pressure | 25MPa | 32MPa |

| Cylinder Diameter | Φ63-160mm | Φ200-320mm |

| Position Repeatability Accuracy | ±0.1mm | ±0.15mm |

| Working Temperature | -10℃~70℃ | -20℃~90℃ |

| Protection Grade | IP65 | IP67 |

| Service Life | 500,000 times | 300,000 times |

---

**Typical Application Scenarios**

▌ **Sawing Feed System**: Precise feed control for circular saws/strip saws

▌ **Log Positioning and Clamping**: Provides a constant clamping force of 200-500 kN

▌ **Transporting Pressure Roll Adjustment**: Automatically adjusts the transporting path of the logs

▌ **Waste Pushing and Discharging Device**: Strongly pushes the cut-off residual wood materials

---

**Product Advantage Matrix**

| **Advantage Dimension** | **Specific Performance** | |-------------|-------------|

| **Accuracy** | Laser calibration guide rail, linear motion accuracy ≤ 0.05mm/m |

| **Efficiency** | Response time < 80ms, cutting cycle improved by 30% |

| **Durability** | 500,000 maintenance-free cycles (ISO 18752 certified) |

| **Intelligence** | Supports industrial 4.0 data connection (OPC UA protocol) |

---

**Customized Services**

- Route customization (200 - 3000mm)

- Installation method (flange/ear ring/hinged)

- Special medium (biodegradable hydraulic oil compatible)

- Explosion-proof certification (ATEX/IECEx)

---

**Quality Assurance**

- Full-process CNC machining (precision IT6 level)

- 72-hour continuous load testing

- 3-year warranty for core components

- On-site dynamic balance adjustment service

Provide precise and reliable hydraulic power solutions for intelligent wood processing! **